In the world of industrial automation, one of the most essential aspects is ‘efficiency’. It is the linchpin of operational success, embodying the seamless integration of various methods and technologies to maximize the output while keeping variables such as time and resources to the minimum. Streamlining processes, optimizing resources, and minimizing downtime are what every industry is looking forward to. One such technology that plays a pivotal role in achieving these goals is Modbus communication.

What is Modbus communication? Modbus communication is a widely adopted protocol in industrial automation, enabling the exchange of data between different devices such as HMIs (human-machine interfaces), PLCs (programmable logic controllers), and sensors. Modbus aids a master-slave architecture where a master device initiates the communication process and manages the flow with multiple slave devices over serial connections like RS-232, RS-485, or the ethernet with the Modbus TCP-IP.

Now, we explore how Modbus communication enhances efficiency in the world of industrial automation and makes a difference for them to maintain a competitive edge:

• OPTIMIZED DATA FLOW

By standardizing communication protocols, Modbus ensures a seamless data exchange between devices in the industrial network. As Modbus facilitates the flow of data over various electronic devices, it eliminates the need for modified solutions to achieve said exchange and fosters simplified integration. This interoperability enhances the flow of data and, hence, leads to streamlined operations.

• FLEXIBILITY

One of Modbus's key features is its scalability and flexibility. Modbus smoothly adapts to growth, whether it is scaling the existing network or employing new ones. As with every other operation, when industrial processes evolve, the presence of the Modbus protocol ensures the integration of additional devices, fluctuating requirements, and changing functionalities. This, in turn, ensures the investments made for and by the industry remain sustainable for a long time.

• CONTROL AND MONITORING

Through Modbus communication, industrial processes can be controlled and monitored in real-time. The various devices connected via Modbus can transmit data instantaneously, enabling an optimized data exchange and the operators to make informed decisions at said instant. Real-time monitoring and control enhance the responsiveness and efficiency of the entire process, be it any specific function the Modbus proves to be advantageous for.

• CENTRALIZED MONITORING

By integrating Modbus displays with supervisory control and data acquisition systems, more commonly known as SCADA systems, industries can achieve centralized visibility and control. SCADA systems collect data from various sources, analyze it, and present actionable insights to operators. Combining Modbus displays with SCADA architectures facilitates efficient asset management while also streamlining oversight and control.

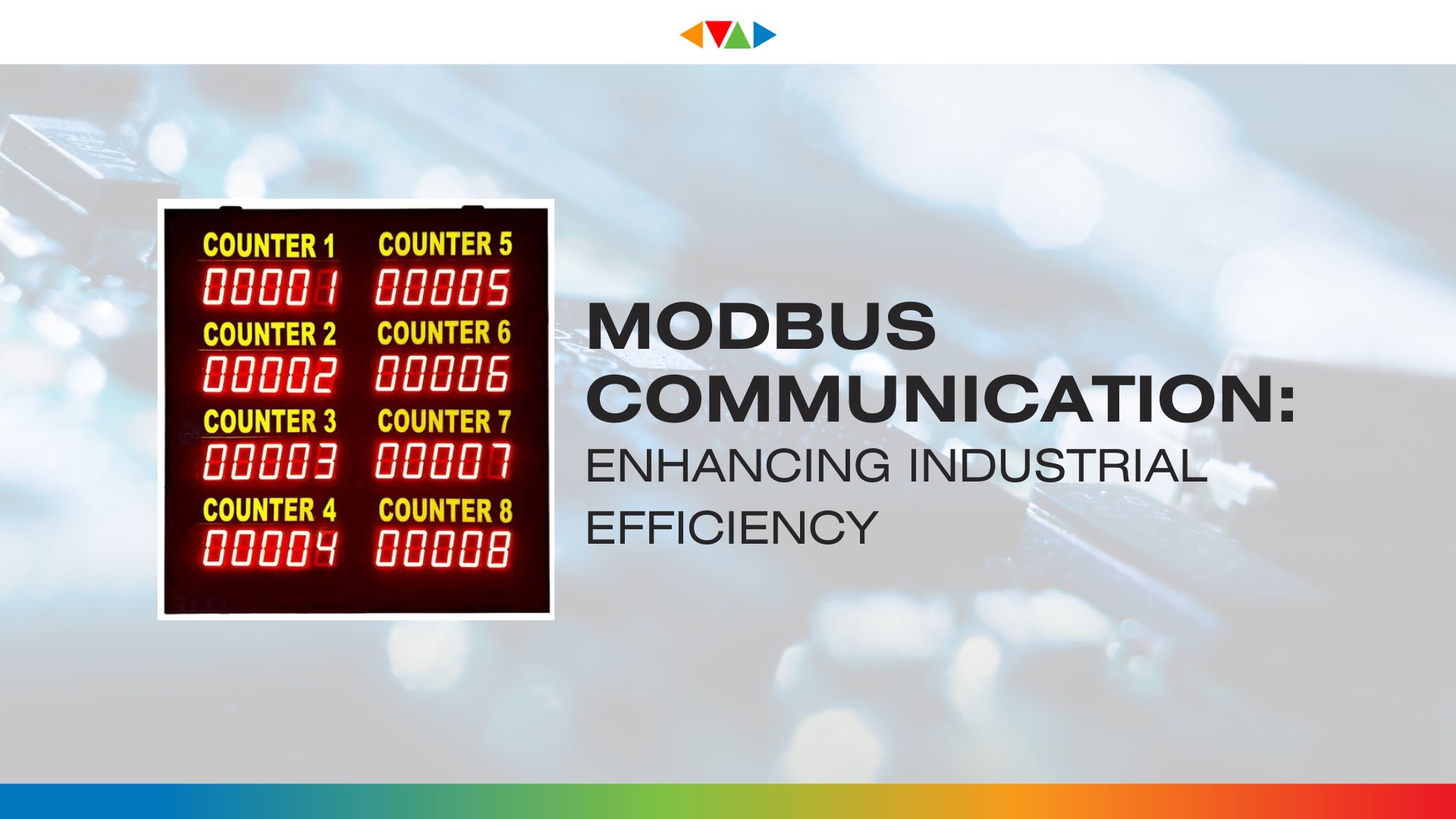

KVAR Technologies Private Limited offer Modbus communication with the wide range of displays that we provide. Be it any industrial display, Modbus, over serial connections like the Modbus TCP/IP or the recommended standard protocols such as the RS-232 and RS-485, is available as an option for streamlined communication and the transfer of information between various devices.

Available as both a Modbus slave and a Modbus master, they typically work on the Modbus RTU protocol. The Modbus baud rate and device addresses are programmable, and the display is customizable as per the user’s requirements. As for indicators, they support 3, 6, or 16 functions and also integer and floating numbers. These indicators are available in 4 to 8 digits and in sizes 0.5 inches to 12 inches.

For more information about Modbus communication and displays, you can mail us at sales@kvartech.com or contact us at +91 8655501507.

-min.png)